Earth continuity conductor to 10hp motor (19/.052) = 6 SWG.The proper sizes of earth continuity conductors for other small motors to the main pairs also given in table 2.2.Īccording to the table, the earth conductor sizes are as follow for this section. In this section, since each motor of 50hp is installed on the far end of the distribution system, therefore, the size of each earth continuity conductor around this section 4SWG. In this section, the biggest motor is 50hp, therefore, the central pair of earth continuity conductor should able to pass any value of fault current produce in the motor. Earth continuity conductor to 10hp motor (19/.052 cable) = 6 SWG.Earth continuity conductor to 15hp motor (7/.052 cable) = 12 SWG.Earth continuity conductor to 20hp motor (7/.064 cable) = 10 SWG.Earth continuity conductor to 50hp motor (19/.064 cable) = 4 SWG.For simplicity, the whole earthing scheme of the factory is divided in three sections.Įxplanation of each section is as follow: In this table, suitable size of earth continuity conductor is given for each size of cable. distribution fuse boards, switch fuses and other electrical wiring etc are not shown in the fig due to complexity)Īfter proper selection of plates and connecting points, now we can find the proper size of earth continuity conductor and earth lead with the help of the following table no 1. Since the example is fully related to the earthing of electrical apparatus only, therefore, there are two separately earth continuity conductor in whole factory (earth continuity conductors of other metalwork i.e. These points are connected via wires flowing through cable ducts. The second point at D and third one at E which is right below the combination switch fuse board and above the cable ducting.

Also, make sure that water purring is possible when needed.Ī connecting point near to main switch board is made at point C. However, for better safety purposes, another pit about 12ft can be dug (on Position B) near to position A for second earth plate installation. Since the water level is deep about 30ft, therefore, we have to dig about 30ft coined and both of the plate can be installed in the same pit then (By doing so, we don’t need two pits as well as, it reduce the installation cost as well).

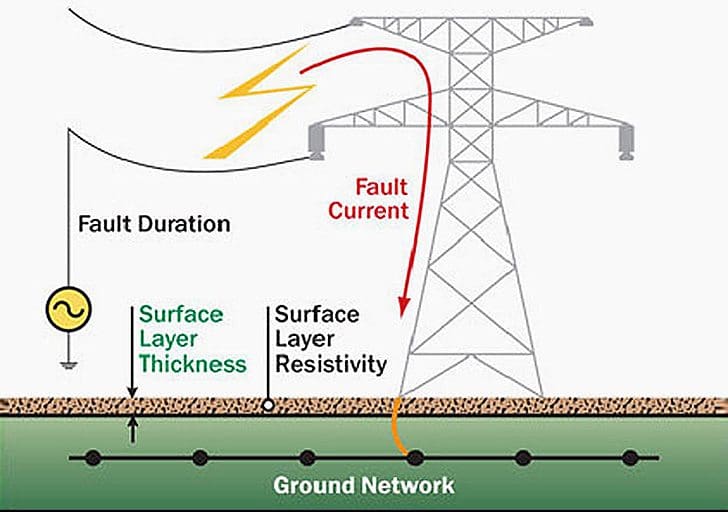

Here, the biggest possible source of fault current is transformer, therefore, at least one earthing plate should be installed near to the transformer and the proper location for earth plate installation (for transformer) is shown in fig 2 (Position A). Layout of the complete factory earthing and grounding system is shown in fig 2 below. Please, keep following.Solution: Finding the Size of Earth Conductor: In the next Article, I will explain Ground Resistance Measurement. (This refers to above ground connections.) Sharp bends must be avoided in all grounding conductors.Some codes require that tinned wires shall be used where the resistivity of the soil is less than 70 Ω/m.Wire size of 35 mm2 (2 AWG) or larger must be stranded.Frequent cross-connections have a relatively small effect on lowering the resistance of a grid, but are useful in securing multiple paths for fault current conditions. The ratio of the sides of the mesh is usually from 1:1 to 1:3, unless a precise analysis warrants more extreme values.Use multiple ground leads or larger sized conductors where high concentrations of current may occur, such as a neutral-to-ground connection of generators, capacitor banks, or transformers. Some codes require a grounding conductor to be buried approximately 3 feet (1m) outside and parallel to the fence. A grid system normally extends over the entire substation switchyard and often beyond the fence line.Ground rods should be placed at the grid corners and never less than 6 feet apart by design. At cross-connections, securely bond the conductors together by thermite welding, brazing, or approved compression connectors. 4/0 or 2/0 AWG bare copper conductors buried 18 inches (0.5 m) below grade, minimum, spaced 10 to 20 feet (3 to 6 m) apart, in a grid pattern. A typical grid system for a substation may include 70 or 120 square millimeters (mm2), No.Within the loop, the conductors lay in parallel lines and, where practical, along the structures or rows of equipment, to provide for short ground connections.Enclosing more area also reduces the resistance of the grounding grid. This practice helps to avoid high current concentration and hence high gradients both in the grid area and near the projecting cable ends. A continuous conductor loop surrounds the perimeter to enclose as much area as practical.

0 kommentar(er)

0 kommentar(er)